This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

According to the International Energy Agency, there will be an estimated 14 million electric vehicles (EVs) sold globally by the end of 2023. This broad electrification is transcending the passenger car, with commercial fleets of both small and large vehicles making the shift from combustion to battery. Technological advancements in high-power infrastructure, charging capabilities and driving efficiency has given businesses clear incentives to transition.

That said, high-power commercial EVs need to be able to perform efficiently to encourage a greater number of businesses to transition to electric. Aside from high-power charging infrastructure, the components used internally for commercial EV designs need to overcome a number of challenges to perform efficiently and safely. Higher voltages lead to increased temperatures, component weight directly impacts driving range and various parts face extreme conditions (dust, water, dirt) for extended periods.

In this guide, we explore the key components that make up high-power EVs and the various challenges they face during integration. Then, we explore the range of components Dalroad offers that not only overcome these challenges, but provide additional features to suit any degree of design complexity.

Key high-power EV components

Cables

EV infrastructure is dependent upon high-performing cable solutions to provide vehicles with the necessary power to each individual component. Whether it’s the battery pack, DC/DC converter, on-board charger, electric heater, electric climate compressor, or high voltage power distribution, cables are the arteries that ensure each system has power.

For high-power EVs, cables need to be suited for continuous and extreme voltage levels without failing due to electrical stress. Because of this, high-voltage cables have additional layers of insulation to control the electric field around the conductor. This results in heavier, bulkier cables that can have an impact on high-power EV design.

For any high-power EV design, it is vital that your components have sufficient thermal insulation to enable design flexibility without adding needless amounts of weight and bulkiness.

Connectors

EV connectors are required by each individual device in an EV to receive necessary power. Due to the high number of individual devices that have varied electrical requirements, a single design utilises a range of connectors that each provide different features.

For high-power EVs, connectors need to be rugged, high-performing and able to withstand high-voltage environments. Outer components such as sensors also face harsh conditions, and require solutions such as being hermetically and environmentally sealed to ensure safety and continuous operation.

When choosing the connector solutions for your design, you need components that have effective vibration shielding and protection from external elements to ensure continuous, safe and long-term functionality.

Harnesses

Harnesses represent the assembly frame that holds internal cables and components in place within a design. Due to the complexity of EVs, there are a multitude of different cables and components that need to be organised to avoid damage and simplify the maintenance process. These harnesses act as points of cable management within a design, whether it is for organisation or protective purposes.

For high-power EVs, these harnesses need to be inherently larger and more rugged to manage the increased size and thickness of cables. Moreover, higher temperatures are a direct result of higher voltages, meaning these harnesses also need to exhibit a level of thermal insulation.

For your high-power EV design, you need harnesses that serve to simplify design complexity with a range of connecting variations and reliable insulative and rugged features.

Terminals

EV terminals are the internal component of connectors that make contact with one another and ensure the joining of two power circuits. These are small conductors that are susceptible to a range of environmental factors such as vibration, heat and corrosion.

For high-power EVs, terminals need to be robust and efficient to enable the continuous power transfer of high voltages across connectors. Additionally, they need to be specialised for specific mating directions and types, making terminal choice a vital component of any EV design.

For your high-power EV design, you need terminals that suit different mating types, can withstand high-voltages and function continuously without a loss to efficiency.

Utilise high-performance EV components that provide the required features for EV designs

- Cables – High-voltage EV cables that are designed to carry varying current capabilities from high to low-medium. Available options provide solutions for wire harness routing challenges where space is limited, design flexibility for hybrid and electric applications and effective thermal insulation.

- Connectors – High quality connectors that showcase great vibration and shielding performance. Our products showcase a revolutionary shielding design, easy mounting holes, and flexible assembly connectivity. We provide a wide range of connectors that have a modular design that also reduces inventory costs and makes assembly simple.

- Harnesses – We provide a wide range of EV and hybrid harnesses to suit each design and level of complexity. Each showcases good thermal insulation, come in a range of sealed and non-sealed variations as well as other features to fit different vehicle designs.

- Terminals – Our high-power terminals are specifically designed to support the increased connectivity requirements in high-voltage interconnection systems of hybrid and all-electric vehicles. We provide products that are suitable for high connector voltage, showcase continuous current capability and are available in different mating directions.

Components for high-power EVs

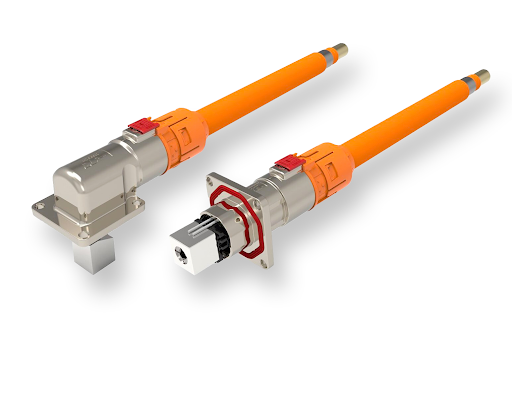

HIVONEX PowerTube connector series

High-power EVs require components that enable them to operate safely and reliably for extended periods in a range of harsh external conditions. The PowerTube connector series achieves this as a modular, scalable and immensely powerful solution. They are available in multiple wire sizes between 35mm² to 150mm², manufactured with scalability and modularity in mind, the PowerTube header is available in either 180° or 90° orientation, as well as up to 3 positions per connector.

Find out more about the HIVONEX PowerTube connector series.

HIVONEX HVA HD400 High Voltage Accessories Connectors

Electrification is expanding to large commercial vehicles, bringing significant demands of EV technology to bring mobility to tonnes on wheels. Not only are components vital for the reliable mobility of these vehicles, but they are necessary for the continuous operation of each individual feature. From HVAC and heaters to hydraulic pumps and electrical power steering, these subsystems need to run safely and reliably for extended periods. HIVONEX HVA HD400 High Voltage Accessories Connectors provide this functionality by being compact, adaptable and resistant to dust, sand, moisture and vibrations.

Find out more about the HIVONEX HVA HD400 High Voltage Accessories Connectors.

Find the perfect components solutions for your design with Dalroad

At Dalroad, we have a team of experienced professionals in the field of high-power EV components. We can advise you on the components that suit your EV design to ensure efficiency, performance and continuous operability. Contact us today to find the perfect component solutions for your design.