This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

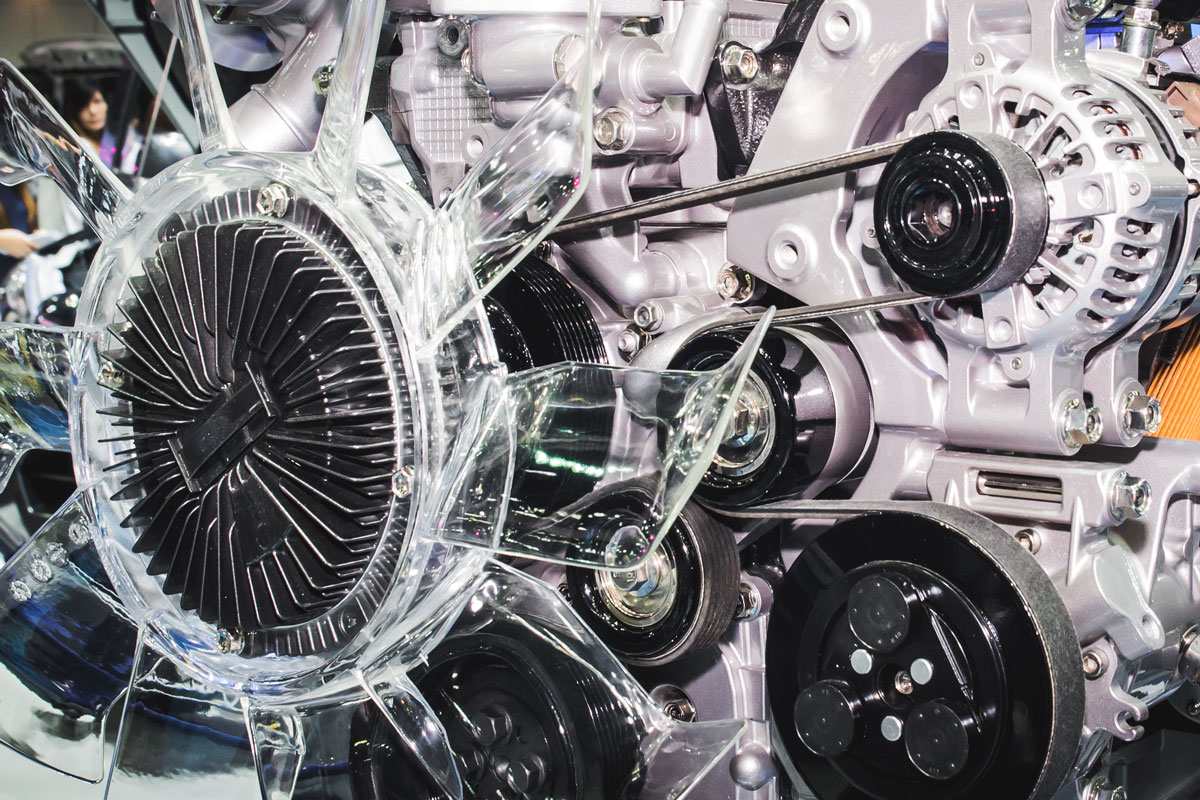

Advancements in electric vehicle components are allowing engineers to design ever more innovative specialist automotive vehicles. New components are helping to improve battery ranges and performance, all while making them safer to drive and easier to maintain.

New features like energy recuperation are also being enabled through newly launched components. This rapid innovation is all being driven by large-scale R&D projects, intense competition and some impressive technical ingenuity with regards to high voltage systems.

These innovations are proving important. Not only are specialist EVs now able to offer better performance, but their total cost of ownership (TCO) and maintenance advantages are making them a more viable option for prospective buyers.

Healthy competition, more innovative components

As companies around the world race to electrify their vehicles, individual governments and economic unions are intent on creating the perfect environments to accelerate this movement. Projects like Horizon 2020 are part of the EU’s wide-scale response to intense global competition. The hope is that EU-designed, scalable technologies help the continent’s automotive industry lead the way for the EV market, in respects of affordability and quality. Competition in the EV market will continue to spark fresh ideas and technologies.

Some of the most experienced, and credible, manufacturers in Europe are partners of Dalroad, including TE Connectivity (with their DEUTSCH connectors), Lear, Savoy, Bosch, Autoelettric and many more. See our full range of automotive components on our website, or get in touch with us and let us know your requirements.

Huge strides in specialist vehicle safety

Specialist vehicles carry incredibly high voltages, much higher than ordinary passenger EVs. For this reason, they bring numerous safety concerns to drivers, operators, design engineers and maintenance engineers. The safety of each of these groups needs to be reviewed thoroughly throughout every stage of the vehicle’s life cycle. Fortunately, components like high voltage connectors have been reinvented to suit high voltage systems, guaranteeing safety throughout powertrains and electrical subsystems.

The influx of sensors and smart responsive systems are also being renewed to improve their safety offerings. These systems are bringing new driver convenience and safety features, improving the awareness of their speed, terrain and driving conditions. Other systems, like collision avoidance systems, enhance the safety of the driver with features like blind spot warning and adaptive cruise control. Brake sensors in specialist EVs can help drivers apply the correct amount of force dependant on road conditions. Beyond that, there are even humidity sensor components. These are designed to improve performance and safety for environments where temperature fluctuations make a difference, in both energy consumption and battery behaviour.

Electrification and customer demand

With the introduction of EU zero-emission targets, electrification is not just the norm, but the expectation. This kind of legislation and customer demand has seen fossil-fuel powered fleet ownership head into decline. As governments continue to incentivise buyers, it’s not only the supply-side that will be prepared, demand is expected to ramp up soon. This widening gap in the market subsequently requires high-quality components that are cost-effective for their vehicle design.

This has brought much-needed attention – and investment – to infrastructure from governments. The UK, for example, has recently passed the Automated and Electric Vehicle Act, laying the path for charging stations to be planned across the nation to accommodate the growing EV sector.

Legislation such as this is playing an important role in the technology standards that manufacturers are choosing to adopt. For example, there is a new version of the CHAdeMO charging standard planned to incorporate ultra-fast charging (400kW). It still leads in the European market, with CCS attempting to come in. Most rapid DC chargers support up to 50kW, while there is a trend of 100-200kW stations being built. However, efforts for 400kW, symbolise attention to the commercial and specialist vehicle market. CHAdeMO’s Secretary General, Dave Yoshida asserted that the new charging is part of a ‘protocol to expand to trucks and buses’, and continued to say that, ‘with the CAN-based communication, it will be a relatively simple but reliable option to charge large commercial vehicles and other industrial applications’.

Integrated components and innovation

According to a McKinsey report on electric vehicle design, manufacturers are moving away from the traditional types of vehicle architecture. Instead, designers are becoming more likely to physically-integrated EV powertrain component sets. This means that power electronics, transmission systems and batteries are being packaged together, gathered into modules using lightweight materials. This not only increases the speed of design, but this design practice can reduce the bill of materials, enable light-weighting and save space.

Integrated vehicle architectures seek to maintain connectivity and prevent micro-separations between individual components. Integration will contribute to a lower risk of electromagnetic interference in specialist vehicles, as they are designed with optimal performance in mind.

The emergence of integrated design and manufacture is an exciting development, and the answer to some of commercial EVs biggest challenges, particularly with regards to development and achieving economies of scale. It’s also beneficial for fleet owners and drivers, for example, less weight means higher-torque and improved range, particularly important for heavier specialist vehicles. It also prevents dangers which emerge from dispersed electric cabling.

Choose the right components

Many of the components built for specialist vehicle electrifications are purpose-built, with innovative technologies that allow them to cope with the strenuous operating conditions and requirements of these vehicles. With more government incentives and supporting infrastructure on the way, the market only looks to be headed one way: more electrification, more innovation, and more demand.

At Dalroad, we work closely with the world’s leading electric vehicle component manufacturers, with all of their latest innovations available to try, buy and design-in to your projects. With the huge sums of investment going into these components, the parts powering designs are only getting better, more robust and lasting longer. If you are working on a live specialist vehicle electrification project, get in touch with our component experts for free no-obligation advice on how to find the best parts for your design.