This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

TE Connectivity, the global leader in connectivity solutions and sensors for harsh environments, have launched a range of high voltage-rated components that are enabling the electrification of specialist vehicles.

The company has a catalogue of high-voltage rated connectors, relays, harnesses, contactors and disconnects; all of which allow high current and potential around hybrid and electric vehicles, allowing them to operate efficiently.

Electrifying specialist vehicles, like trucks and buses, differs to that of passenger cars. Connectors and electronics need to work towards a different set of goals. They need to be rugged yet light, durable yet safe and capable of operating in harsh environments.

Rated for higher voltages

To power the motor and onboard electronics in an electric vehicle, high voltage ratings are necessary. For specialist vehicles, with greater power requirements, electrical components need to deal with extremely high voltages.

The automotive EVC 250-800 main contactor has a continuous current of up to 250A and a voltage rating of up to 800V. The EVC 250, therefore, is capable of handling the power-hungry demands of higher voltage electric and hybrid vehicles. This might include applications involving electric turbochargers, air-conditioning compressors, and pumps, as well as additional features necessitated by specialist requirements.

Ordinarily, components built for higher voltage and continuous current operations are bulky, heavy and difficult to integrate. However, TE’s unique small packaging size allows for the contactor to be deployed inefficiently; so, for example, they can be designed into battery disconnect unit layouts and the like. This removes excessive weight, contributing to lightweighting and range improvement efforts.

Designed for durability

The EVC 80 and EVC 250-800 contactors, Mini K HV Precharge Relays and AMP+ connectors are all capable of handling even the most extreme voltage levels, up to 850VDC in the EVC 250-800 contactor. What’s more, the components are hermetically and environmentally sealed making them robust enough to weather the harshest of conditions. This is perfect for specialist vehicle applications – such as in the municipal and military sectors – where every component is subject to high vibrational levels, dust, water and even corrosive chemical contact.

Inherent safety

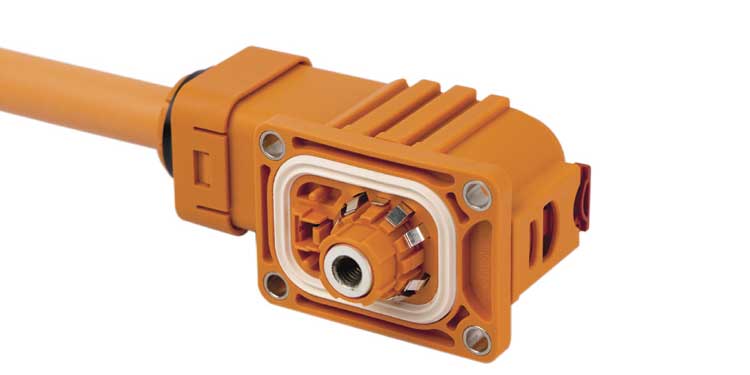

The AMP+ HVA 280 connectors offer a wide variety of device and wire harness applications like battery pack, DC/DC converter, on-board charger, electric heater, electric climate compressor, and high voltage power distribution. The connectors are unique, in that they feature a discrete header design that optimises packaging and manufacturing efficiency. The design includes a two-stage floating latch which increases safety by strengthening the connection.

Lightweight innovation

Another plus for EV manufacturers is that AMP+ components are made to be lightweight. When it comes to building electric vehicles, or indeed hybrid vehicles; reducing weight is the name of the game. The less weight your vehicle carries, the more efficient it will be. Due to the weight of the battery, and various electrical systems, EVs tend to be heavy. But for specialist vehicles, which can be very large and often have additional features; weight reduction is even more critical.

Conclusion

TE’s range of high voltage components has been launched to meet the demands of an increasing number of electrification projects, which seek to increase voltage levels inside a vehicle’s architecture. As requirements grow, and the specialist vehicle market continues to inflate, this trend will only become more dominant. Components inside a high voltage machine need, of course, to be high-voltage ready; but they also need other mechanical properties such as durability, size and weight efficiency, as well as having been tested rigorously to ensure they will last a vehicles life cycle. TE’s high voltage components tick all these boxes, and more, to request a quote on TE’s latest components please get in touch with one of our experts.