This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

This is the first in a series of articles outlining the must-know factors when dimensioning a variable frequency drive for a drive system. This article reviews load characteristics, a critical element that will be determined by the end application. Read our other articles in this series on dimensioning for power supply and motor.

Probably one of the most important aspects of correctly choosing a variable frequency drive (VFD) is ensuring that it has sufficient capacity in terms of KW and nominal current rating to allow the motor to generate the required torque right across the intended speed range while allowing for any periods of overload.

We can categorise the types of loads into:

- Constant torque, otherwise known as heavy duty (HD).

- Variable torque, or normal duty (ND).

- Constant power (CP).

The three common load characteristics

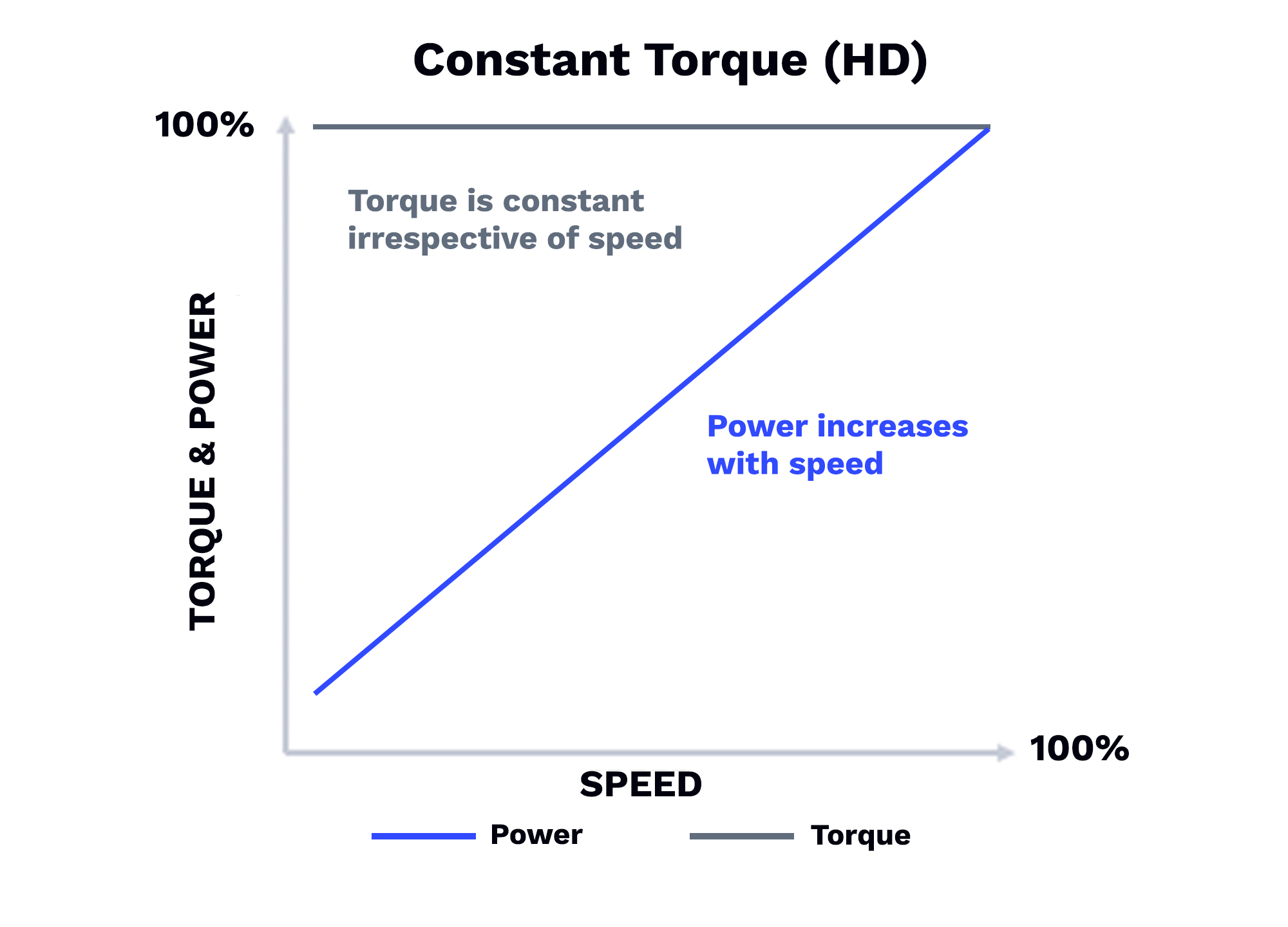

Constant torque

The very first step of dimensioning a drive system comes from considering the nature of the driven machine, i.e. its application. For motors that are handling loads such as augers (drills), screw compressors (for example chillers), positive displacement pumps and conveyors, they will be considered HD because of their constant torque profiles.

This chart shows that power is proportional to speed and the starting torque can be high with some degree of electrical overload possible.

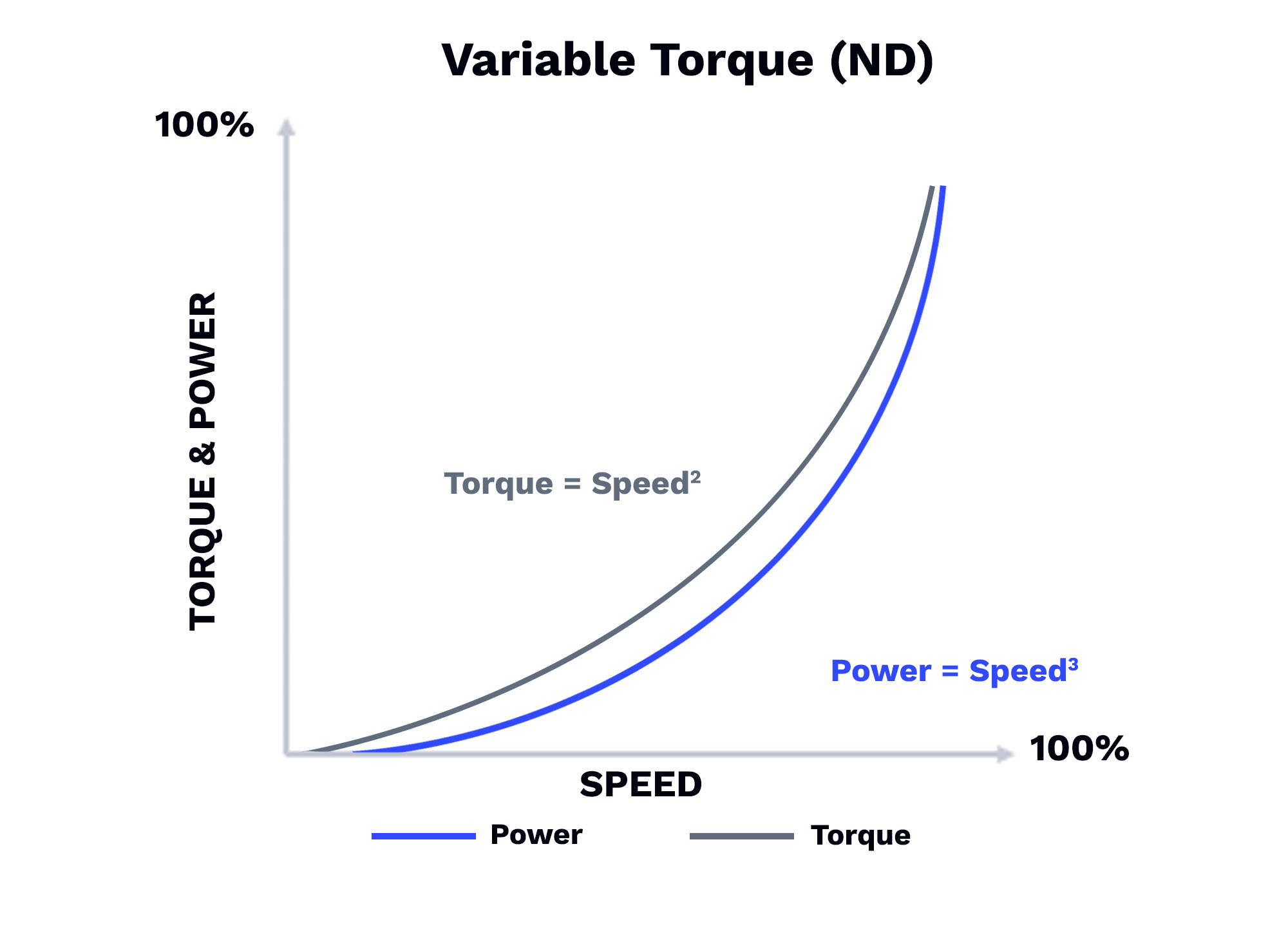

Variable torque

Motors handling applications such as fans and centrifugal pumps require little overload at start. Their starting torque is also relatively low by comparison with some HD applications.

This chart demonstrates what is sometimes referred to as a quadratic load. At 50% base speed, the torque required is around 25%. Power, in this instance, is proportional to speed cubed. Torque, meanwhile, is proportional to speed squared.

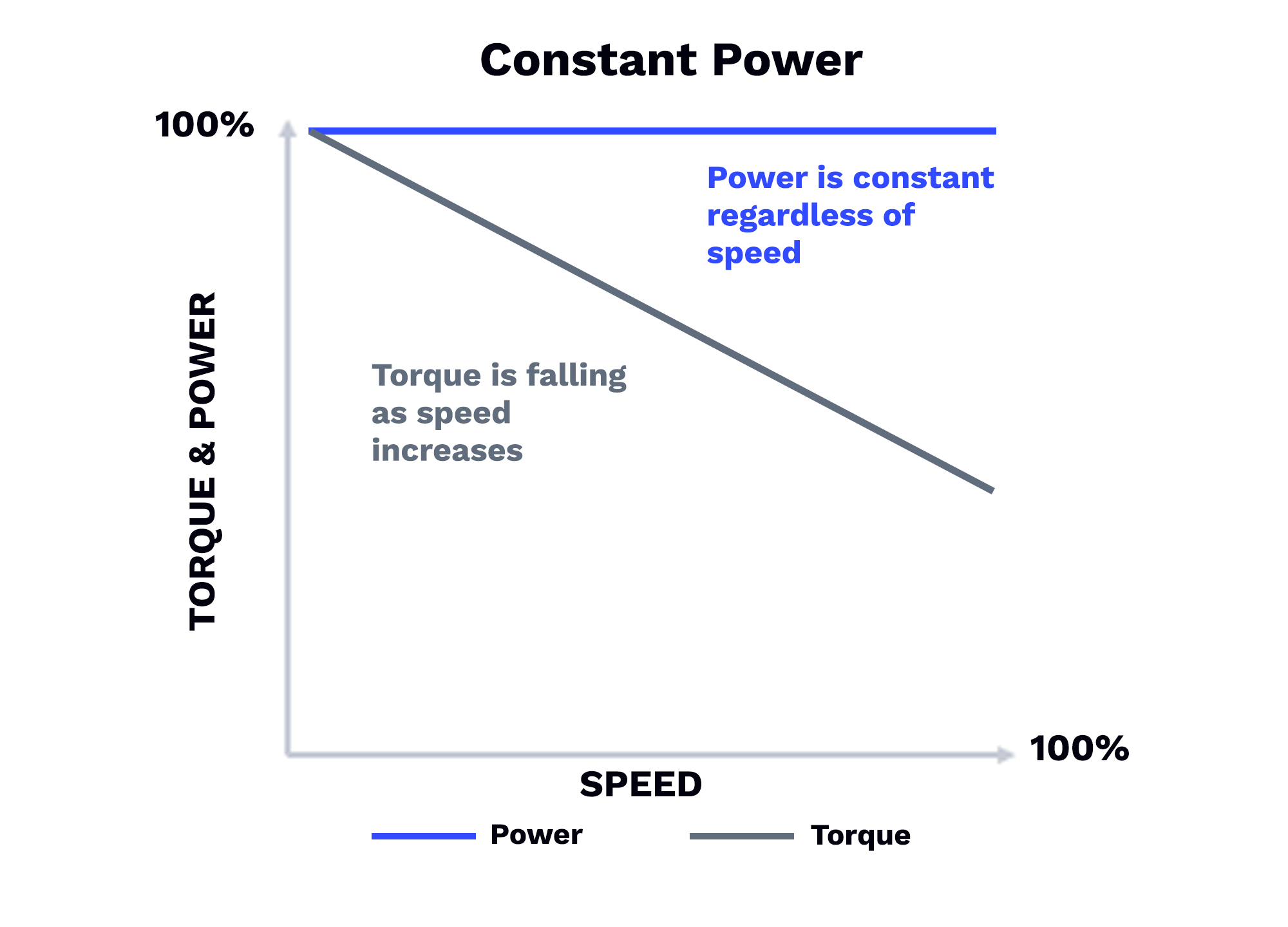

Constant power

Many machine tools, like grinders and lathes, and winders load a motor with constant power (CP). This means that power remains at a constant, irrespective of the speed or torque.

Continuous and cyclic loads

Each of the three common load types can either be categorised as continuous or cyclic. In the case of a cyclic load, you will need to factor this in when dimensioning your drive system, as there could be possible overload repetition caused by frequent starting and stopping which can compromise the motor’s thermal capabilities.

Regenerative applications

A growing number of machines utilise an induction motor that can operate regeneratively. At specific points in the operation, stored inertia in the driven machine can cause the motor to act like a generator and can result in the VFDs DC bus voltage to rise, which in turn left unchecked can cause the VFD to trip and the load to freewheel out of control. These regenerative applications usually require installation of dynamic brake resistors (DBR) which will burn off excess regenerative energy as heat. This kind of solution is not always the most efficient method of controlling regenerative energy, but it may be the lowest up-front cost option.

Key takeaways

There are three common types of load handled by motors:

- Constant torque / heavy duty (HD)

- Variable torque / normal duty (ND)

- Constant power (CP)

- Each of these load characteristics can be either continuous or cyclic – cyclic loads can create specific challenges regarding the overall performance of the drive system and should be carefully considered during the planning stages.

- Applications that may be regenerative may require some sort of mitigation technique either in the form of dynamic braking resistors or by fitting a VFD’s with an active ‘front end’ can be a more efficient solution as they will allow regenerative current to flow back into the mains without the need for braking resistors to be connected.

Looking for specialist support?

Dalroad helps OEMs dimension and install industry-leading, innovative variable speed drives across a wide variety of industries.

We supply high-quality variable speed drives that can help you maximise the performance of your application, while adding in automated control functionality and boosting the energy efficiency of your project.

To learn more about our expert support service, get in touch with one of our variable frequency drive experts today.