This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

TE Connectivity’s new BCON+ high voltage connection system is a versatile, compact, robust, and touch-safe solution for interconnecting cell modules inside a traction battery and high voltage connection points outside the battery.

The BCON+ connection system combines the advantages of solid steel-to-steel bolt termination with the extremely low contact resistance of copper contact elements. In all unmated and mated states, the mechanism is touch-safe. It interconnects with a wide number of conductors and cross-sections in a variety of ways.

ELECTRIFICATION SAFETY

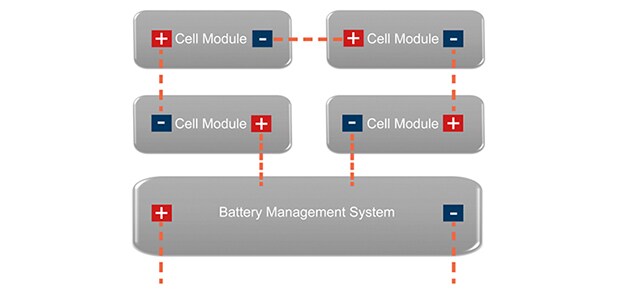

The adoption of electrified propulsion systems in vehicles is being driven by the increased demand to minimise carbon emissions. The battery is the primary source of renewable energy, while in a hydrogen fuel cell vehicle, the battery serves as a peak load buffer. As a result, the battery is at the centre of powertrain electrification. Batteries are made up of several different cells that are grouped into modules. In these systems, batteries are made up of several different cells that are grouped into modules. Energy must flow safely in and out of the battery during all vehicle operating modes. As a result, module links must be capable of carrying currents of up to 600 amps for minutes throughout a high-power charging cycle, but up to a factor higher during dynamic drive modes that last just seconds.

The physical layer for battery protection (overtemperature shut-down), battery control (charge conditions, e.g. state-of-charge SoC), and cell-balancing are made up of battery module connections (charge voltage equalisation between cells with different SoC levels). Each transmission battery module must have failproof electrical connections to ensure these operations. This necessitates fully engineered contact systems that are capable of supporting maximum mobility over the vehicle’s entire lifetime (typically 300,000 km/186,500 miles over ten years), as well as being stable enough to preclude friction and temperature stress from adversely influencing the contacts’ mechanical and electrical properties. To avoid possible high-voltage and high-power hazards in both passenger and commercial vehicles, and to ensure consumer and service staff protection, as well as legislation, contacts must be completely touch-safe.

Full touch protection of the connection systems in both mated and unmated states allows for careful handling of battery modules during battery assembly. Battery modules can be simply and safely operated by qualified electricians in routine maintenance or restoration situations throughout the span of a vehicle’s life, without the need for costly special equipment or complex safety procedures.

TE Connectivity has developed an innovative interconnection system for traction batteries based on its vast automotive experience in copper and aluminium connection technologies. The new BCON+ bolt termination system meets the requirements of demanding applications. The BCON+ high-voltage connection system is a bolted termination that can be easily unmated (for diagnosis or recycling) and is completely touch-safe with IPxxB protection in accordance with ISO 20653. To ensure robustness and easy handling of contacts in manufacturing conditions, the mechanical direction of the bolt termination and the electrical path (low-impedance copper-to-copper connection) are functionally separated from each other.

The BCON+ bolt termination system is designed to provide optimum stability in module connections and other power terminations in a wide range of electrical efficiency architecture interconnection applications. Figure 1.

BCON+ CONNECTION SYSTEM

Electrified Vehicles

In an electrified vehicle, battery module contacts must satisfy stringent specifications. As a result, both conductors and connections were designed to withstand continuous currents of 400 amps (plus short peaks of up to 1,200 amps) and voltages of up to 1,000 volts, while operating consistently at average battery ambient temperatures ranging from -40 to +80 °C. The finally selected connector materials will operate reliably even up to 140 °C. The main challenge was to achieve very low contact resistance at the individual contact points with minimal power losses, close to those of commercial battery cells. BCON+ contacts have a touch resistance of <10 μΩ on either side of the complete interconnection system.

According to manufacturer test specification LV215, the module connector is configured to attain vibration tolerance for severity level 3 (LV214, SG 3), compliant with environmental regulations for unsealed systems.

This form of termination mechanism must be simple to assemble and secure to use. It must also allow for configuration flexibility depending on the vehicle and battery configuration. Module interconnections must also withstand up to 25 mating and bolting cycles and have a lifetime requirement of 300,000 km (186,500 miles) or ten years.

BCON+ Bolt Termination System

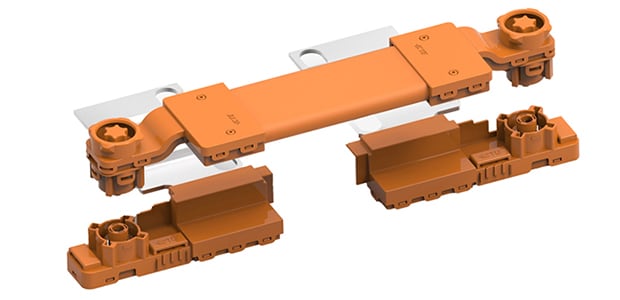

Aluminium and copper profiles are used at the battery interface, and flexible conductor types are used on the steel-to-steel bonding side of a BCON+ battery module.

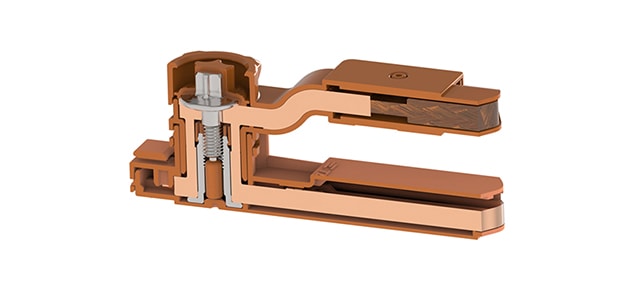

Flat aluminium busbars, which function as a contact to all cells intertwined inside the module (as seen in figure 2), are commonly used for actual cell interconnection. Each module is connected to the high voltage battery system via flat bolting connections made of solid copper (Cu-busbars). These integrate the bottom of the electroplated copper interface with a tempered steel thread insert. An inserted bolt integrated into the termination of a stranded copper wire (high voltage cable), which is converted to solid copper or into a circular massive conductor, serves as the interface for the plug-in socket (figure 2).

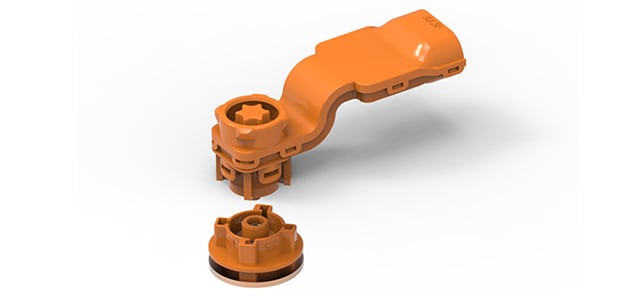

The high voltage cable contact is mated with the female copper interface in BCON+ termination (figure 3). Matching coding (= correct interconnection) triggers a pre-latching process, which secures the cable to the busbar and enables easy two-handed assembly during the bolting process (also over-head assembly).

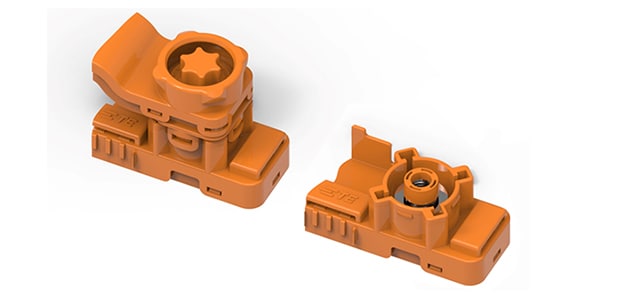

To avoid inadvertent finger contact with live parts, all contact parts are enclosed in upper and lower casings made of glass fibre reinforced plastic (IPXXB = no contact with objects >12 mm diameter and max. 80 mm length). Plastic components are flame resistant to the HB standard, and V0 protection is available upon request. The casing design maximises the amount of space available for installation (figure 4), providing optimal protection even in tight spaces. The live pieces are protected by casings, which are coated with silicon or have a high-temperature resistant glass fibre cloth jacket.

Various welding or bonding technologies are used to establish interconnections between aluminium busbars and solid copper interfaces (i.e. the interconnection between stranded conductor on the cable side and copper interface).

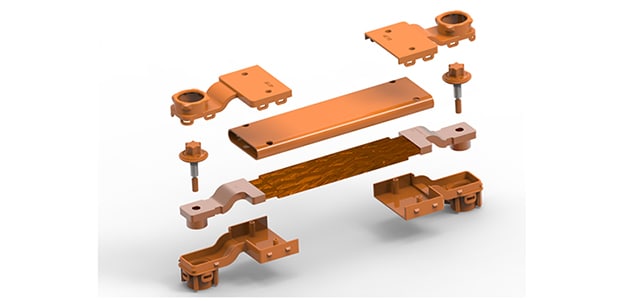

TE Connectivity produced the captive M5 bolt used to tighten the round copper interfaces out of tempered material. The bolt head is plastic over-moulded and secured with a standard hexalobular internal. Figure 5 shows the breakdown of the BCON+ bolt termination connector.

This construction applies mechanical tension only in the steel-to-steel system, fully separated from the electrical interconnection function on the copper-to-copper current path established before by mechanical pre-tension (figure 6).

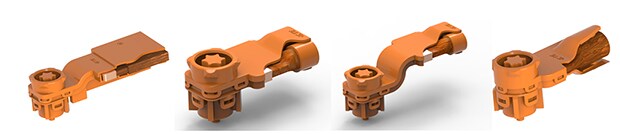

Strong copper busbars are available in a wide range of profiles to overcome various touch issues, including straight or angled variants with optional offsets (= varying offset heights).

To avoid inadvertent mating, contacts on the bottom side of the interconnection may be differently coded and rotated in 90° increments.

Space Saving

Connections are possible with round solid conductors, stranded wire conductors (round and flat), and (straight and offset) copper flat contacts. Figure 7 depicts a variety of geometric options. The BCON+ bolt termination is suitable for conductors with cross-sections ranging from 16 to 100 mm2.

The system components are perfectly suited due to their incredibly small scale.

SUMMARY

The TE Connectivity BCON+ connection system is a highly functional low-resistance bolt termination system for steel-to-steel bolting that is both secure and completely touch-safe, even in tight spaces. At the same time, the BCON+ bolt termination’s low contact resistance, combined with its high reliability and protection, makes it a secure, secure high voltage connection for battery modules and other high-power applications outside the battery.

Different contact configurations and geometrical contact formats (offset compensation, complex harness routing) are achievable with only one system thanks to the simplicity of interconnection solutions (various copper flat contacts shapes, various conductor options). Safe assembly is supported by various coding choices and 90° increment rotating. The bolt termination is pre-latched during mating to make handling easier during production. Touch-safety following IPXXB prohibits users from handling live parts during all related vehicle life stages (production, maintenance/repair – including in non-specialised garages –, and recycling).

The touch-safe, lightweight BCON+ bolt termination system is a modular, versatile connection solution for the battery.

The touch-safe, compact BCON+ bolt termination system is a flexible, scalable connection solution capable of being mass-produced for the battery. The BCON+ connection system is ideal for high volume applications due to its touch-safe handling in both unmated and mated states and low-resistance electrical coupling, making the BCON+ module interconnection is a key component for facilitating safe operation and handling of high voltage battery systems.

Contact Dalroad for further information on the BCON+ Interconnection System at projects@dalroad.com.